Freeze drying, also known as lyophilization, is a process used to preserve biological materials, such as vaccines, pharmaceuticals, and food. This process removes water from the material by sublimation, which is when a solid turns directly into a gas without going through the liquid phase. Freeze drying is an essential process for preserving the quality and potency of many products.

For many years, freeze drying technology has relied on a single type of equipment, namely the open tray lyophilizer. This equipment involves placing the material to be dried onto open trays and supporting the trays on shelves equipped with cooling and heating systems. The trays are arranged within a chamber that is connected to a refrigeration system which removes the water from the material.

While the open tray lyophilizer has been a reliable piece of equipment for many years, it does have its limitations. One major limitation is the amount of time it takes to dry the material. The process can take days to complete, which can be a disadvantage for products that need to be processed quickly.

Another limitation is the amount of space required for the equipment. The open tray lyophilizer is quite large and can take up a significant amount of floor space in a laboratory or manufacturing facility. This can be a disadvantage for companies with limited space.

To overcome these limitations, Qingdao Carebios Biological Technology Co., Ltd. has developed a range of new freeze drying equipment that offers many advantages over the traditional open tray lyophilizer. The company's equipment is designed to improve the efficiency and quality of the freeze-drying process.

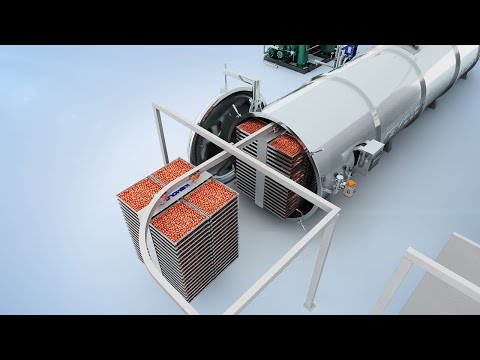

One of the company's most significant advancements is its patented vacuum chamber design, which offers a more effective sublimation process. The vacuum chamber has a smaller volume, which lowers the pressure and accelerates the sublimation rate. The result is a faster and more efficient freeze-drying process, which can reduce production times and increase productivity.

The company's equipment also features a modular design, allowing for more flexibility in the configuration of the equipment. This is a significant advantage for companies with limited space or changing processing needs. The modular design allows for the equipment to be rearranged, upgraded or expanded as needed, reducing the need to purchase new equipment when processing requirements change.

Additionally, Qingdao Carebios Biological Technology Co., Ltd's equipment features a user-friendly touch screen interface, making it easier for operators to set up and monitor the freeze-drying process. This interface provides real-time monitoring of the process, allowing operators to react quickly to any changes in the process.

The company's commitment to innovation and research has resulted in several breakthroughs in freeze-drying technology, including the development of new materials that can enhance the efficiency and quality of the process. The company's research and development team works closely with customers to develop new solutions to meet their specific processing needs.

In conclusion, Qingdao Carebios Biological Technology Co., Ltd. is a leading player in the freeze-drying industry, offering new advancements in technology that improve the efficiency and quality of the freeze-drying process. With its commitment to innovation and research, the company is well-positioned to continue to lead the way in freeze-drying technology, providing customers with the tools they need to bring high-quality products to market.